Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chris' Reef Savvy Shallow (1 Viewer)

- Thread starter ChristopherKriens

- Start date

-

- Tags

- acropora frag reef savvy shallow

deneed4spd

Senior Member

Get a roof rack for the M3. Easy to take on and off when you need to carry long items. Where it gets tricky is when you have two baby seats in the back.

You car seat looks like your fish tank plumbing. Most people would diagnose this as a problem. Here, I'm just more concerned with getting water in my frag tank before you get water in yours.

Just a coincidence... You'd better hurry, I think I have everything I need to get things flowing.

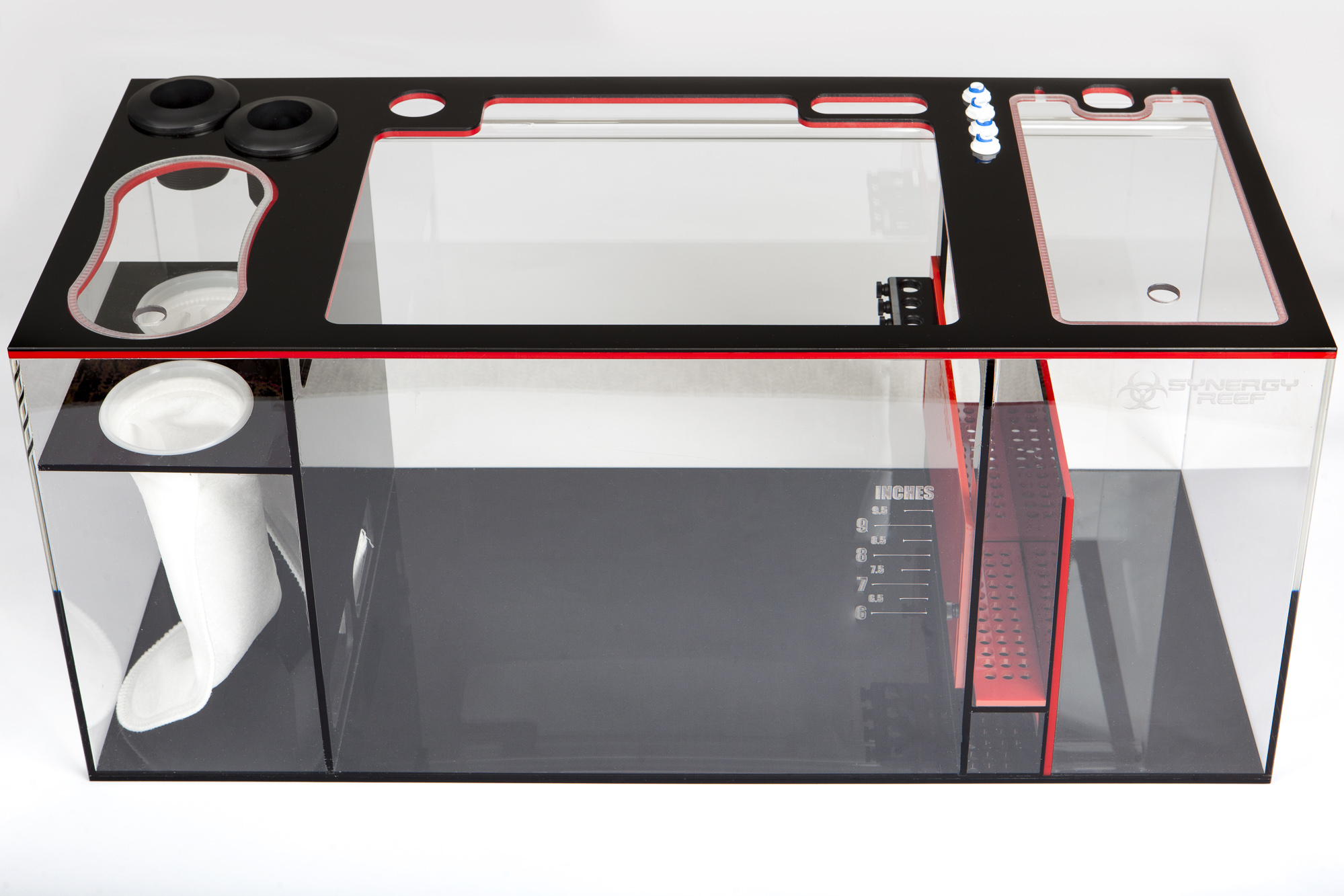

Sump is unpacked and in place. The two-toned cross laminate looks really nice. The sump dimensions are 34" x 15" x 15" for a total volume of around 30 gallons. There are three main chambers; the overflow on the left with dual filter socks, the skimmer area in the center, and the return section on the right. The center chamber is open and the other two have removable polycarbonate covers. There's also a sealed tube on the rear where the LED strip slides into place.

A quartet of John Guest fittings mounted above a high flow area so I can dose all the things.

The skimmer section has an adjustable-level baffle to keep the water level at the optimal level for any skimmer.

Baffle adjustment with heights etched into the acrylic.

Probe holder built onto the baffle.

Overflow bulkheads, primary and secondary.

Laser etched logo.

I'll grab some shots of the auto top off reservoir too for tomorrow. Wild game is distracting me.

Last edited:

Davy Jones

Senior Member

Why am i surprised that not only do you have one of the nicest looking tanks ive seen but also drive my favorite car? Jealous.

Got started plumbing this weekend, but decided to do a couple of things differently so I'll have to wait until midweek to get a few more plumbing bits from BRS. Installed a GFCI outlet, not sure if I'll use it or not; I do like the idea of not getting electrocuted, but the risk of a false positive has me worried.

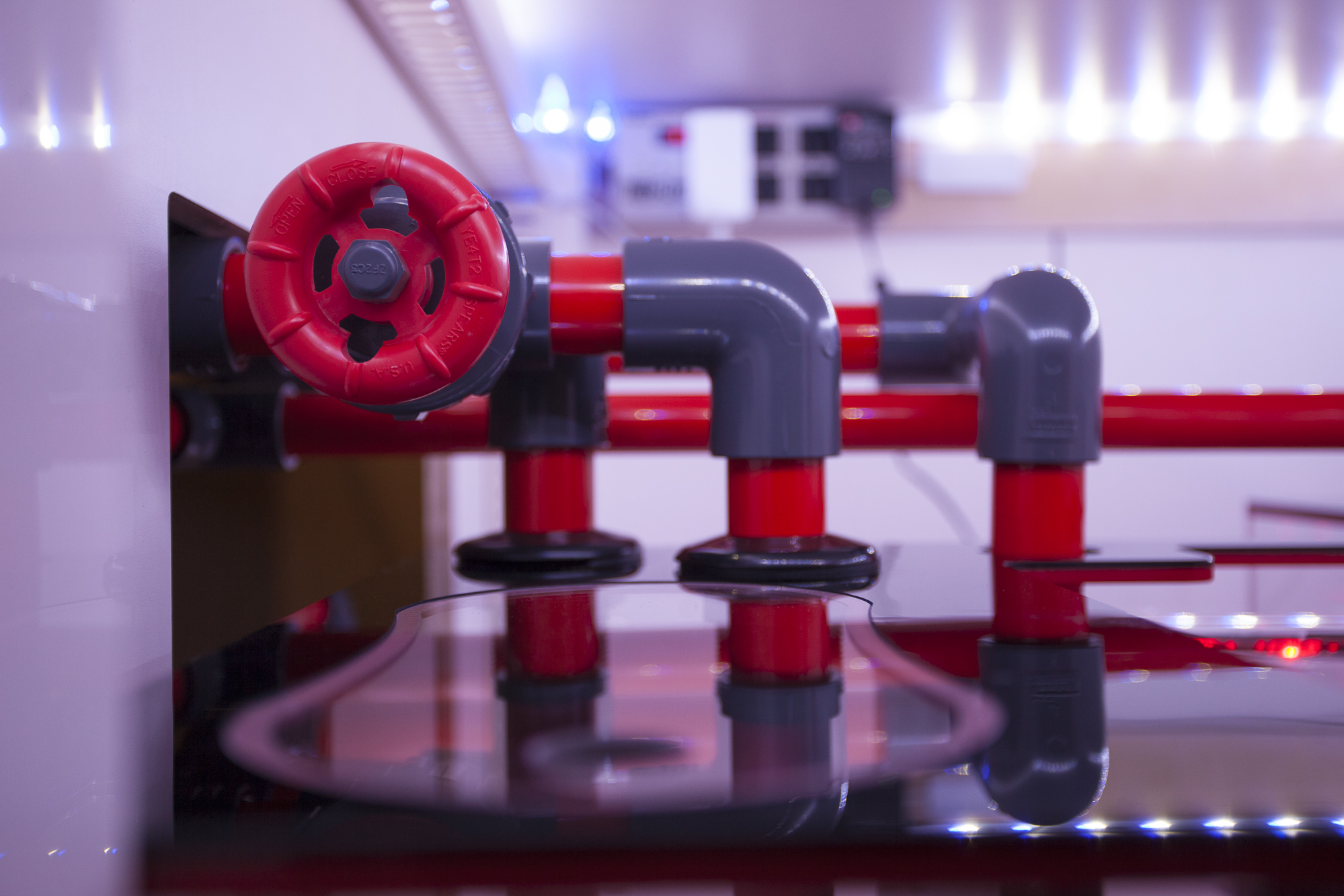

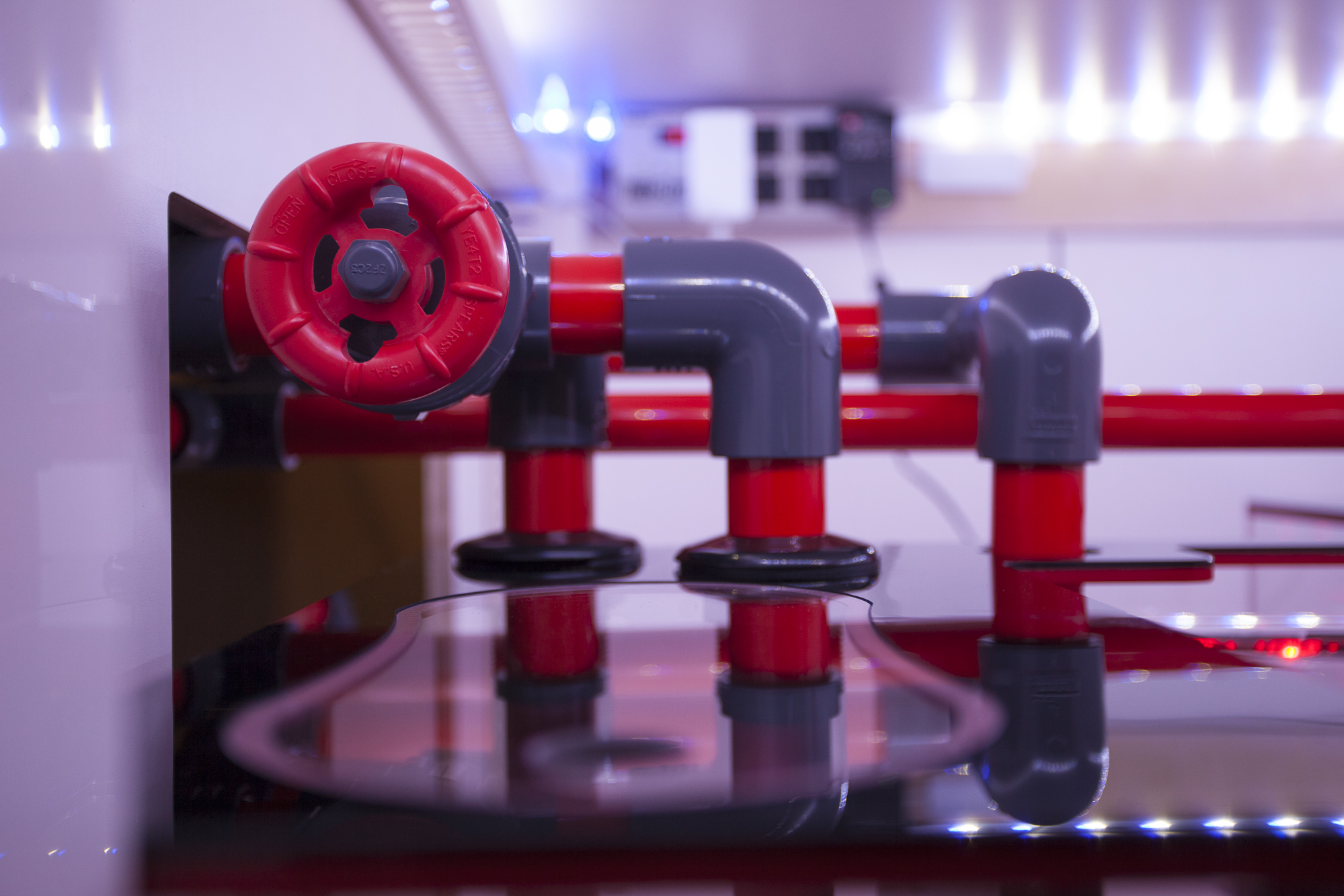

Plumbing project start.

Here's the layout currently. Basic power will come from a Tripp Lite 8-Outlet Switch. I'm sure I'll add an Apex at some point. I found some small, white raceways that aren't too ugly so I mounted a few runs with sticky tape so I can rearrange once I start actually running power.

The return line will have to travel the length of the sump with this arrangement, but the drains (plumbed on the upper left) have a nice, short drop. The top off will be fillable from the front access. This stuff only takes up about half of the area under the stand, so there's some space for a small coral quarantine.

The etched stuff catches the lights nicely.

Plumbing project start.

Here's the layout currently. Basic power will come from a Tripp Lite 8-Outlet Switch. I'm sure I'll add an Apex at some point. I found some small, white raceways that aren't too ugly so I mounted a few runs with sticky tape so I can rearrange once I start actually running power.

The return line will have to travel the length of the sump with this arrangement, but the drains (plumbed on the upper left) have a nice, short drop. The top off will be fillable from the front access. This stuff only takes up about half of the area under the stand, so there's some space for a small coral quarantine.

The etched stuff catches the lights nicely.

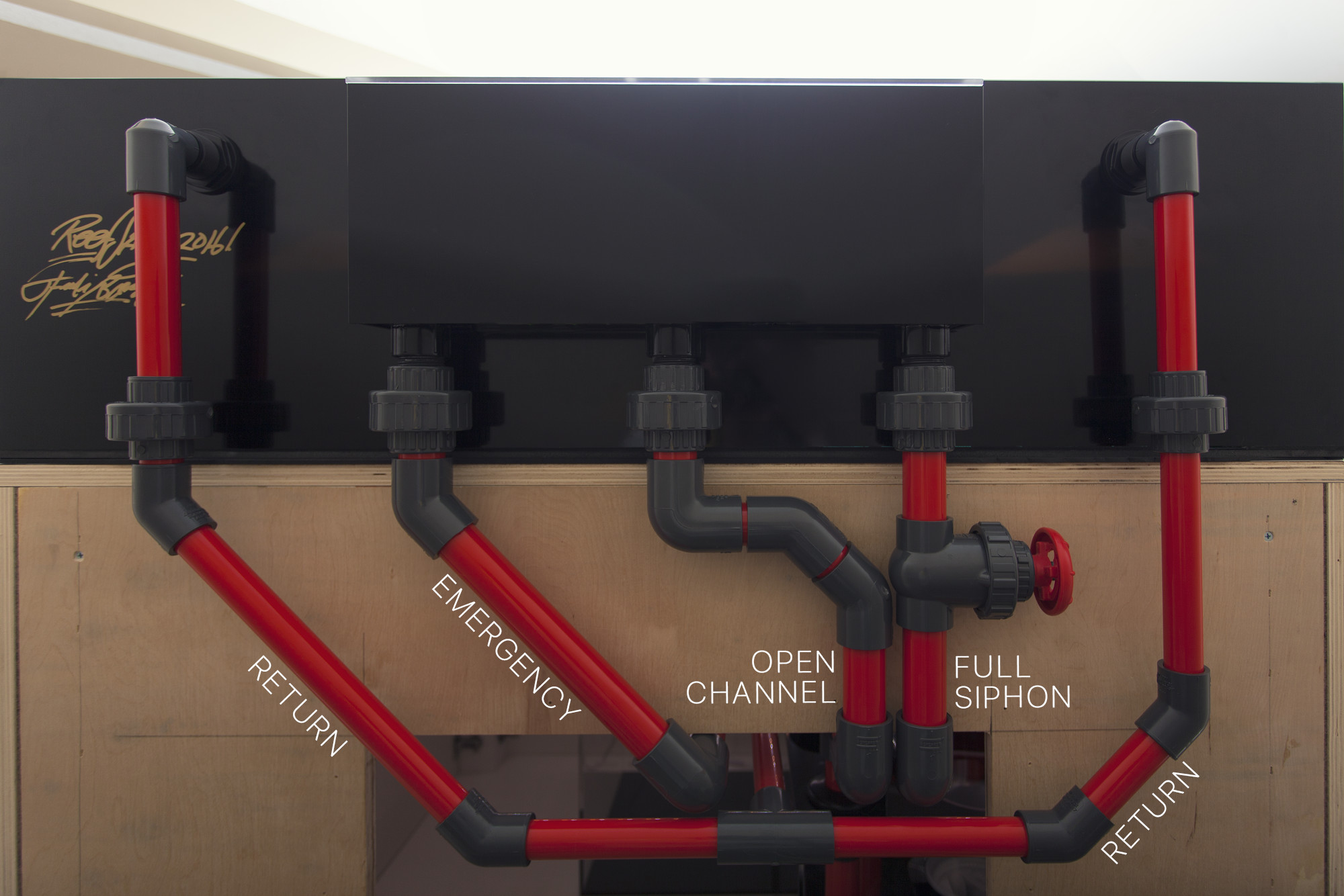

Dry fitting the plumbing. This is my first attempt at Bean Animal, so if anything is off feel free to embarrass me publicly about it. The return line split isn't symmetrical, but I hope that the flow isn't effected too much.

I don't like having a 90º right away on the center drain, but I don't have enough room to use 45's. The right side return line will make using the gate valve a little challenging when it's against the wall, but it's usable.

I don't like having a 90º right away on the center drain, but I don't have enough room to use 45's. The right side return line will make using the gate valve a little challenging when it's against the wall, but it's usable.

I did an official (mostly) Bean on my frag tank, it's ok. Don't think I have enough height difference between full and open channel, it's a thru the back Bean so not so changeable. With your external overflow I'd assume you are not gluing the fittings I'm place inside the box (for cleaning purposes also) so you can tinker with the stack heights.

Make sure it's easy to get at the gate valve.

Make sure it's easy to get at the gate valve.

Not sure what it looks like on the inside but would you be able to put the gate valve underneath the stand so it's more accessible?

jlanger

@thatfishcookieguy

Lifetime Member

Event Committee

Meeting Host 2020

Meeting Host 2021

Meeting Host 2022

That plumbing looks sexy, but an unfinished back of the stand? :doh:

If you're worried (anal) about the uneven return flow with non-symmetrical lines, you could add a gate valve to each line after the split and regulate the flow to your liking. It would be adding more pieces to your plumbing, but I've seen it done like that somewhere.

If you're worried (anal) about the uneven return flow with non-symmetrical lines, you could add a gate valve to each line after the split and regulate the flow to your liking. It would be adding more pieces to your plumbing, but I've seen it done like that somewhere.

Dry fit looks good. I hope the pipe is fully seated in the fittings so you don't loose that difference when bonding and not have it line up the same anymore. You could swap out the 90 and doubled 45's for two sweeps on your open channel. They don't carry them at brs but you can look here: http://stores.drainageproducts.us/1-pvc-schedule-80-sweep-90-1-4-s-x-s/

Thanks for all the advice!

Turns out it does fit.

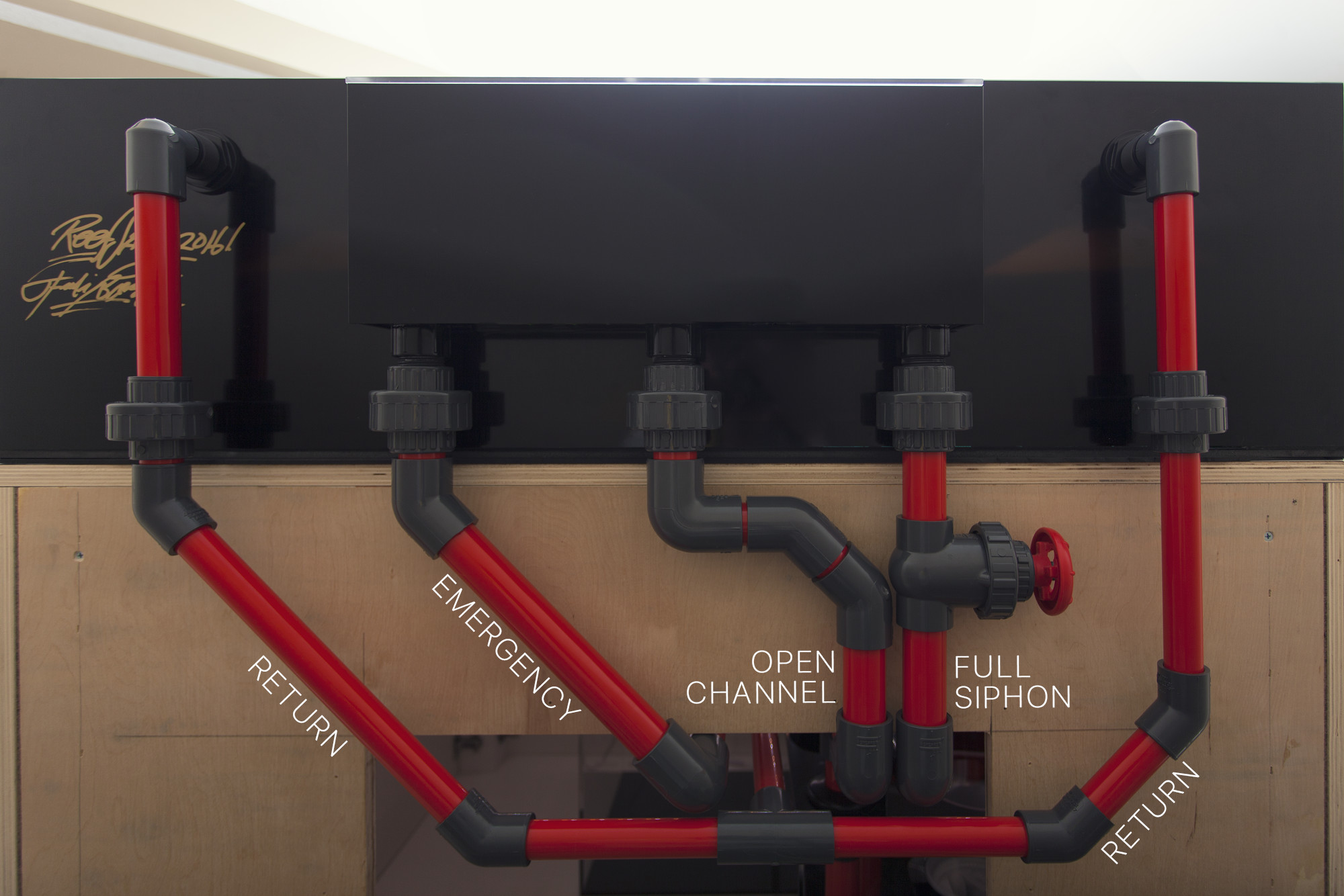

The size of the gate valve does force a slight angle on the open drain, but I think it's worth it as it also lets me remove that 90 elbow. I also added a pair of ball valves to the return so they can be tweaked from the sides. I also learned you can rotate the handles 180º of the Cepex ball valves, in case the long side doesn't fit the application.

Here's the second draft:

Not sure what it looks like on the inside but would you be able to put the gate valve underneath the stand so it's more accessible?

Turns out it does fit.

The size of the gate valve does force a slight angle on the open drain, but I think it's worth it as it also lets me remove that 90 elbow. I also added a pair of ball valves to the return so they can be tweaked from the sides. I also learned you can rotate the handles 180º of the Cepex ball valves, in case the long side doesn't fit the application.

Here's the second draft:

Love the newer configuration!

Great clean lines and layout

Great clean lines and layout

jlanger

@thatfishcookieguy

Lifetime Member

Event Committee

Meeting Host 2020

Meeting Host 2021

Meeting Host 2022

Much better.

Here's an observation... If you need to remove the return lines at the bulkhead, will you need to spin the plumbing? If so, is there enough clearance from the overflow box? I'm not saying that you will ever need to do that; just looking out for future "what-if's"; leaky bulkhead/fitting.

And I'm going to bring an eraser the next time I visit.

Here's an observation... If you need to remove the return lines at the bulkhead, will you need to spin the plumbing? If so, is there enough clearance from the overflow box? I'm not saying that you will ever need to do that; just looking out for future "what-if's"; leaky bulkhead/fitting.

And I'm going to bring an eraser the next time I visit.

Much better.

Here's an observation... If you need to remove the return lines at the bulkhead, will you need to spin the plumbing? If so, is there enough clearance from the overflow box? I'm not saying that you will ever need to do that; just looking out for future "what-if's"; leaky bulkhead/fitting.

And I'm going to bring an eraser the next time I visit.

To keep clearance low, the elbows coming off the return bulkheads are street fittings, which will be glued into place. If I have to take things apart above the unions, I'll be using a hack saw :2gunsfiring:. The next time you visit, you won't be able to reach those pencil lines!

It turns out that the tube that's added to the sump to house the LED bar prevents any sort of realistic plumbing options. Both the 3/4" return and the 1" emergency line are obstructed; even a bare pipe can't pass straight through without an angle. This is a disappointing design decision by Synergy Reef, and the LED bar was clearly an afterthought that was shoehorned into an existing layout. They did warn me about using 1" plumbing on the return, but evidently this also includes 3/4", and probably 1/2" to be honest.

I have a couple of things I can try but I may end up just removing the bar so I can do things the right way. I did try a Uniseal on the emergency line, but the hole isn't quite the right size and there isn't a lot of tolerance on hole sizes for Uniseals to work properly.

Here is the return hole with a 3/4" Bulkhead for scale.

And here's the emergency hole with a 1" bulkhead.

Last edited:

Eek very poor design . It's those little things you would think they would test out before shipment.

Can't tell by the pics but any chance the led bar can be cut and just be eliminated from that area? I know a lot of led "strips" have cut points every few inches.

Would suck to lose the led lights but function beats wow factor

Can't tell by the pics but any chance the led bar can be cut and just be eliminated from that area? I know a lot of led "strips" have cut points every few inches.

Would suck to lose the led lights but function beats wow factor

I'm not quite sure how those sumps with bulkheads work but any chance you can flip the bulkhead around and put the flat side down and the threaded side up? If need be you could use a street 45 to get around the led strip.

That or you could cut the bulkhead so that there is still enough space to screw the nut on tight but not enough to prevent it from hitting the strip. This is of corse if you don't need fittings after the bulkhead

That or you could cut the bulkhead so that there is still enough space to screw the nut on tight but not enough to prevent it from hitting the strip. This is of corse if you don't need fittings after the bulkhead

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)